Matériau: acier au carbone/acier inoxydable/aluminium/cuivre/tôle galvanisée disponible

Épaisseur: 0.05 pouce

Tolérance: ± 0.005 pouce

Processus de fabrication: dessin profond

Traitement de surface: revêtement en poudre/peinture/anodisation/sablage/revêtement de zinc etc disponible

Étirage profond en aluminium, emboutissage profond de la coque, emboutissage profond du boîtier, étirage profond en acier inoxydable, étirage profond en laiton

Stretch forming is a stamping method that uses molds to form flat blanks into open hollow parts. As one of the main stamping processes, stretching is widely used. The stretching process can be used to produce thin-walled parts with cylindrical, rectangular, stepped, spherical, conical, parabolic, and other irregular shapes. If combined with other stamping processes, more complex shaped parts can also be manufactured.

Use stamping equipment for product stretching and forming, including stretching, re stretching, reverse stretching, and thinning stretching.

Stretching processing: Using a pressure plate device and utilizing the punching force of the convex die, a part or all of the flat sheet metal is pulled into the cavity of the concave die to form a container with a bottom. The processing of the side walls of containers parallel to the stretching direction is a simple stretching process, while the stretching process for conical (or angular) containers, hemispherical containers, and parabolic containers also includes expansion processing.

Re stretching processing: For deep stretching products that cannot be completed in one stretching process, the formed products need to be re stretched to increase the depth of the formed container.

Reverse stretching processing: The process of reverse stretching the stretched workpiece from the previous process, turning the inner side of the workpiece into the outer side and reducing its outer diameter.

Thinning and stretching processing: Use a punch to squeeze the formed container into a concave cavity slightly smaller than the outer diameter of the container, reducing the outer diameter of the container with a bottom and thinning the wall thickness. This not only eliminates wall thickness deviation but also makes the surface of the container smooth.

When using stamping equipment for metal stamping and stretching processing, there are 16 types available:

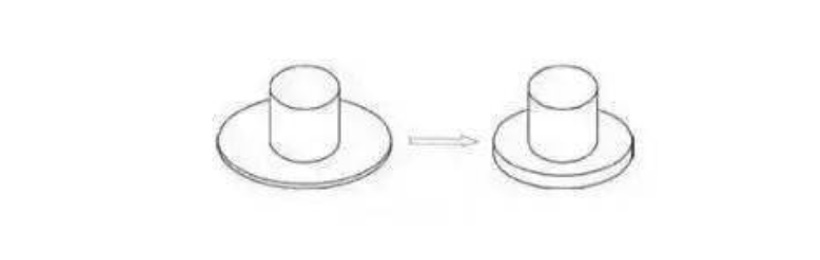

01

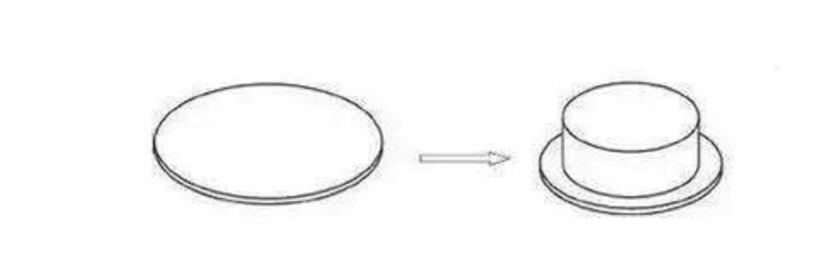

Round drawing

Stretching of cylindrical products with flanges. The flange and bottom are both in a flat shape, and the cylindrical sidewalls are axisymmetric. The deformation is evenly distributed on the same circumference, and the blank on the flange undergoes deep drawing deformation.

02

Ellipse drawing

The deformation of the blank on the flange is tensile deformation, but the amount and ratio of deformation change correspondingly along the contour shape. The greater the curvature, the greater the plastic deformation of the blank; On the contrary, the smaller the curvature, the smaller the plastic deformation of the blank.

03

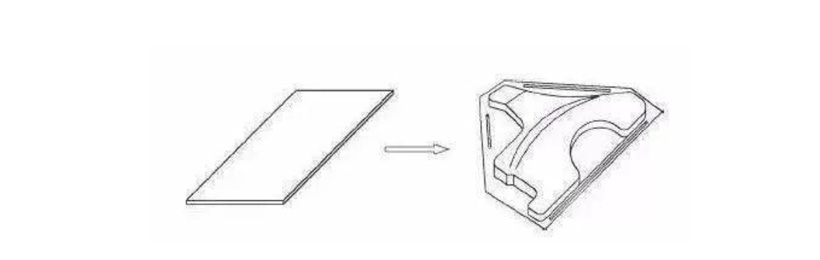

Rectangular drawing

A low rectangular part formed by one-time stretching. When stretching, the tensile resistance at the corner of the flange deformation zone is greater than that at the straight edge, and the degree of deformation at the corner is greater than that at the straight edge.

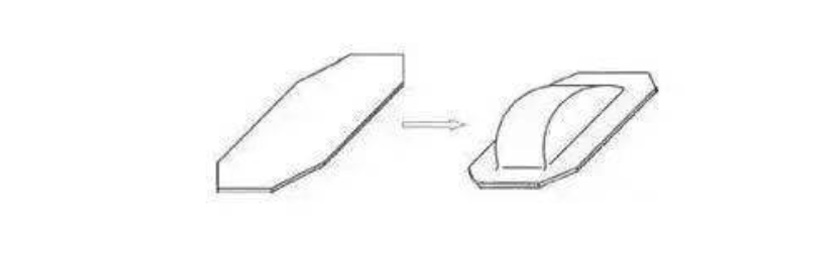

04

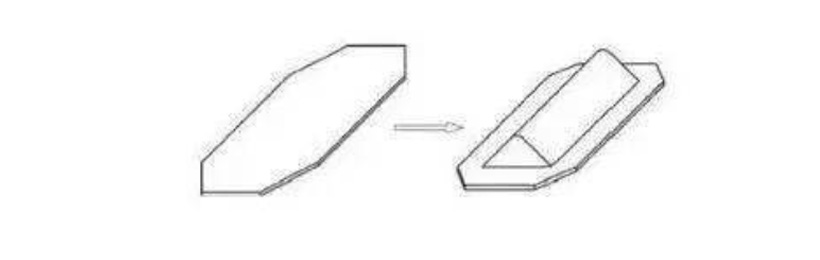

Hill drawing

When the side wall of the stamped part is inclined, the side wall is suspended during the stamping process and does not adhere to the mold until the forming is completed. The deformation characteristics of different parts of the sidewall during forming are not completely the same.

05

Hill drawing

The deformation of the billet during the forming process of the hill shaped cover plate is not a simple tensile deformation, but a composite forming process where both tensile and bulging deformation coexist. The deformation of the billet on the pressing surface is tensile deformation (radial is tensile stress, tangential is compressive stress), while the deformation of the billet inside the contour (especially in the central area) is bulging deformation (both radial and tangential are tensile stress).

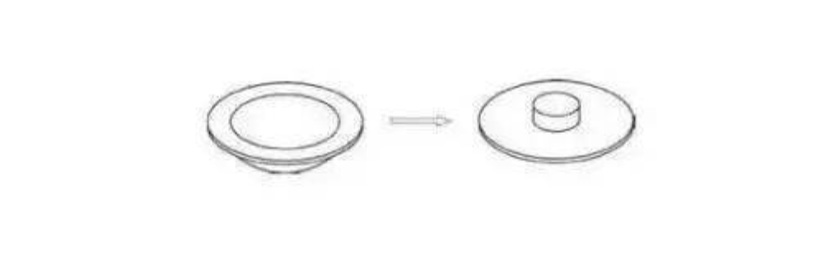

06

With flange Hemisphere drawing

When the spherical part is stretched, the blank locally contacts the spherical top of the convex mold, and the rest is mostly in a suspended and unconstrained free state. Therefore, the main process problem of stretching such spherical parts lies in the severe thinning of the local contact part or the instability and wrinkling of the curved part.

07

Flange drawing

Perform shallow stretching on the flange portion of the stretched product. Its stress-strain situation is similar to compression flange. Due to tangential compressive stress, it is prone to wrinkling, so the forming limit is mainly limited by compressive wrinkling.

08

Edge drawing

Perform angular re stretching on the flange of the stretched product in the previous process, which requires the material to have good plasticity.

09

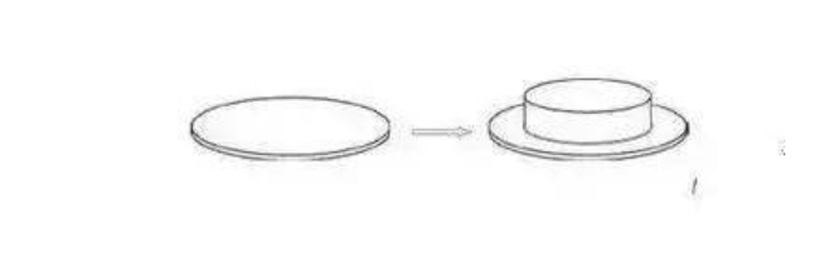

Deep drawing

Stretching products that exceed the stretching processing limit need to undergo two or more repeated stretching processes before they can be completed. The product that has undergone deep stretching processing at the front workstation is re stretched in the depth direction. The wide flange stretching part is stretched to the required flange diameter during the first stretching, and the flange diameter remains unchanged during subsequent stretching.

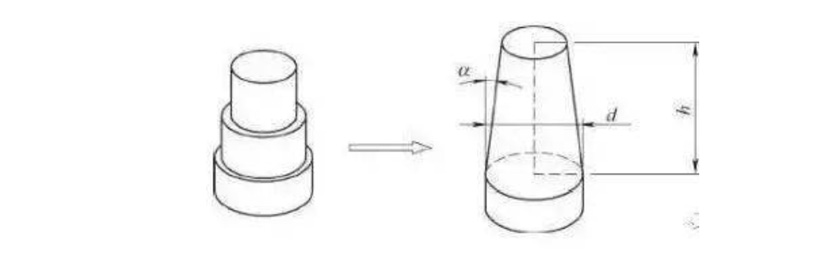

10

Taper drawing

H/d>0.8 α= Deep conical parts with a depth of 10 ° to 30 °, due to their large depth, have a greater degree of deformation of the billet. The forming force is transmitted only through the local area of contact between the billet and the convex die, which can easily cause excessive thinning or even fracture of the billet. It needs to be gradually formed through multiple transitions. The step stretching method is to first stretch the billet into a step shaped transition piece, whose step shape is tangent to the inner shape of the conical part, and finally form a cone. The stretching frequency and process of the stepped transition part are the same as those of the stepped cylindrical part.

11

Rectangular redrawing

The deformation of high rectangular parts formed by multiple stretching is not only different from that of deep cylindrical parts, but also greatly different from that of low box shaped parts. The picture shows the changes in the shape and size of the workpiece during multiple stretching processes during the processing of high rectangular box parts using a multi station automatic conveying press.

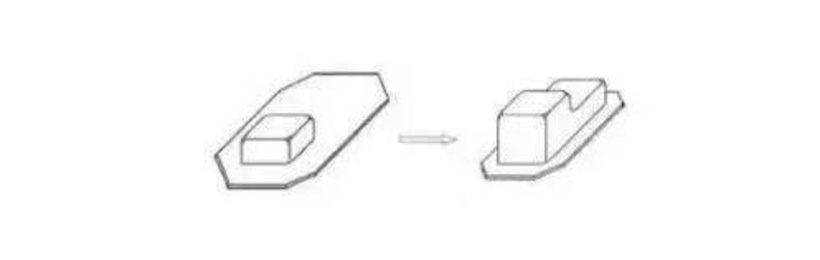

12

Surface forming

Curved surface stretching forming is a stamping method that reduces the outer flange part of a metal flat billet and elongates the inner flange part, resulting in a hollow product with a non straight wall and non flat bottom curved surface shape.

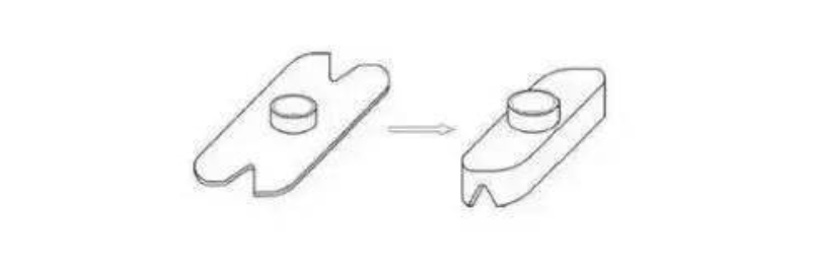

13

Step drawing

Re stretch the left initially stretched product to form a stepped bottom on the right side. The deeper part undergoes deformation in the early stage of stretching, while the shallower part undergoes deformation in the later stage of stretching. The sidewalls in the changing parts of the steps are prone to inducing shear stress and deformation.

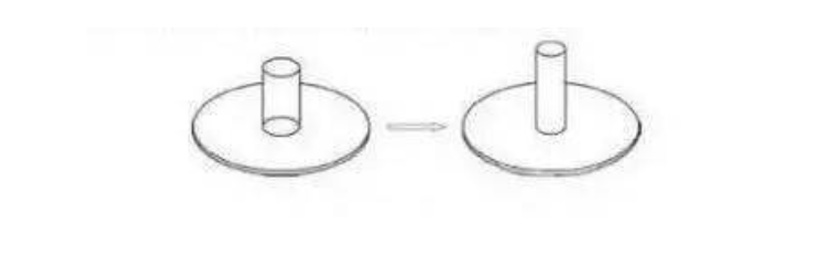

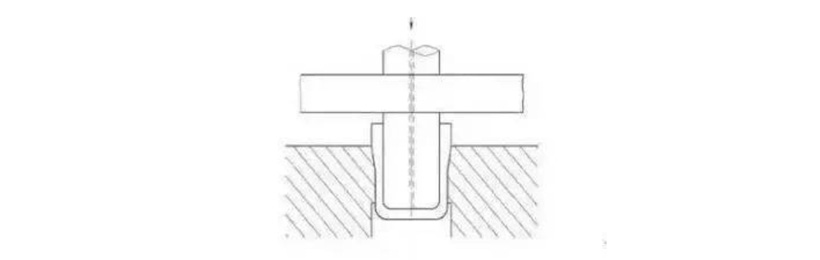

14

Reverse drawing

Reverse stretching is a type of re stretching that involves stretching the workpiece processed in the previous process. The reverse stretching method can increase radial tensile stress and achieve good results in preventing wrinkling. It is also possible to increase the stretching coefficient of re stretching.

15

Ironing

Unlike regular stretching, thinning stretching mainly involves changing the thickness of the cylinder wall of the stretched part during the stretching process. The gap between the convex and concave molds is smaller than the thickness of the blank. When the straight wall part of the blank passes through the gap, it is under a larger uniform compressive stress. During the stretching process, the wall thickness becomes thinner while eliminating the deviation of the container wall thickness, increasing the smoothness of the container surface, and improving accuracy and strength.

16

Panel drawing

Panel products are sheet metal stamping parts with complex surface shapes. In the stretching process, the deformation of the blank is complex, and its forming properties are no longer simple stretching forming, but composite forming with both deep drawing and bulging